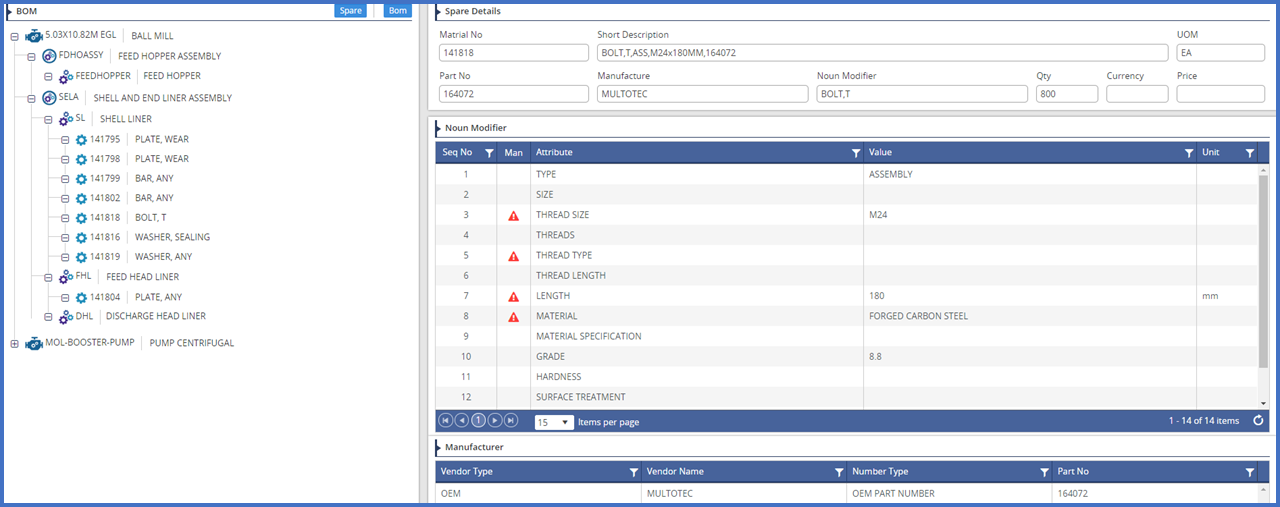

Midas asset management module enables users to capture and record the master data essential for plant asset management activities. This allows multi-site asset-intensive companies full visibility of assets and hierarchies, plant maintenance routines, Bills of Material and linkage to spare parts. The Midas asset hierarchy is structured in accordance with ISO 14224 standards, configurable for the specific layout of each company and operating plant. The elegant and interactive Midas GUI records individual asset criticality, risk and impact assessment. The Midas asset module’s SPIR component replaces traditional SPIR spreadsheets with a highly configurable portal, linked to assets, spares and dictionaries, allowing spare parts records to create accurate data at source. Based on the ISO 14224 compliant equipment classification structure, Midas enables the structured classification of all assets and equipments, captures documents, and displays the asset hierarchy, Bills of Material and functional location.